The Search Press Production Department’s role is to make sure the process of printing our books goes off without a hitch. Production Controller Louise talks to us about the day-to-day management of book printing, and how a book goes from concept to finished product.

Once a book has been digitally designed and edited, what’s the next stage?

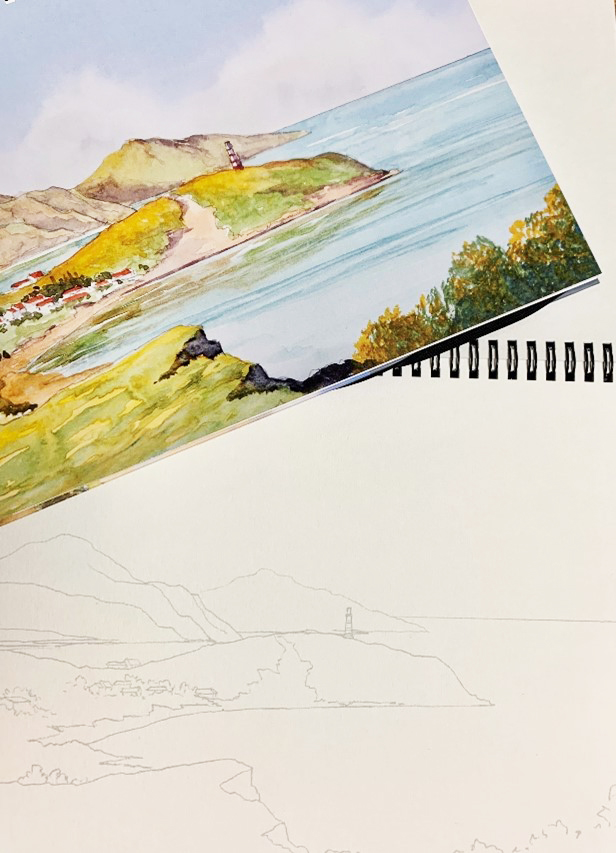

When we have been handed high-resolution files for a new book, Production has digital colour proofs made up for every page so we can see what the book will look like before we print thousands of copies. These colour proofs are reviewed by our editorial and design team to make sure everything looks right, and then we give the printers the green light to print large quantities.

So how do those files translate into the physical proofs, and then final book?

The printer will create a template using both the corrected files and the proof from which to print the book. The template is a large, thin metal sheet which prints 8 or more pages at a time. The colour is made by balancing inks, which are made up to industry standard colours known as CMYK process. The ink runs over the plate, and is pressed against the paper very quickly, as hundreds of sheets per minute run through a conveyor-belt-style machine. The large pages are then sent to the binding line, where they are folded and collated into a book block. That book block is then whizzed through a machine that sews the sections together; it also glues on the cover and trims the book to the right size.

In some cases, covers are laminated or coated before the book is bound – this gives the paper its shiny quality, and can be used over lettering to give an embossed effect.

Are there a lot of decisions to make when choosing a company to print a book?

Absolutely! Production handles the more practical side of the publishing business, which means making cost-effective, informed choices over paper types, binding types and book formats.

For example, in 2019 we collaborated with Daler-Rowney to add specialist watercolour paper to one of our popular series titles, The Paint Pad Artist.

All our books are printed on sustainable and responsibly-sourced papers and all our printing companies are certified and follow all the necessary regulations for paper sourcing and workforce management. We additionally publish books with outlines printed on tracing paper for our budding artists, and iron-on transfers, made using speciality ink, for our embroidery market.

We’ve also published many books that have full-size patterns in pockets which are glued to the back cover; they are printed separately and inserted after binding.

All these features make Search Press books unique, and therefore complex to produce! There’s certainly an element of choosing which printers can produce high-quality products using these materials.

What other aspects of production are there?

Once a book has been printed, it’s packed up carefully into boxes, ready for Production to organize global shipping to distributors. We work closely with agents to ensure the swift and safe arrival of thousands of copies across the world, so you can buy them!